Accident Scene Assistance

Accident scene assistance 24 hours, 7 days, Australia wide, on our Assistance hotline. (02) 8425 4926

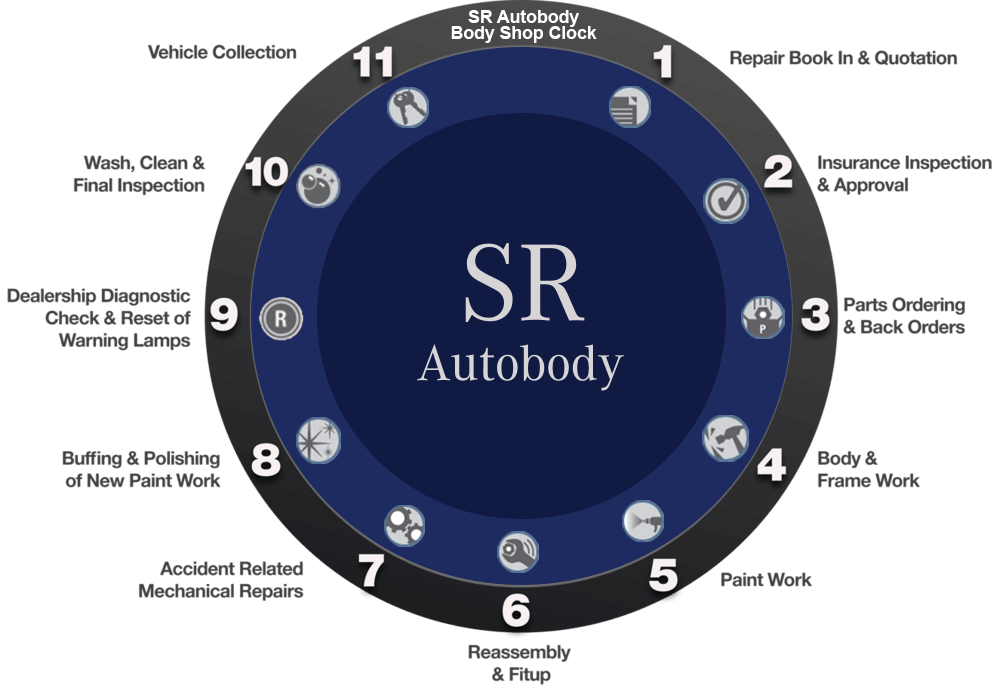

Repair Book In & Quotation

Repair Book In & Quotation

Your car will be inspected for damages and the best method of repair decided. We will book your car in for repairs at our repair facility located near Hornsby station.

Average Repair Times

- Front or rear bumper only 2-3 days

- Small work 1 ½ weeks

- Medium work 2 ½ weeks

- Large work 3 ½ weeks

- Extra large work 6+ weeks

Assistance With Claim Lodgement

Take advantage of our claims professionals to assist you with your claim lodgement, from the comfort of our offices, Our customer service staff are there to simplify this process for you, which, when unassisted, can be very time consuming and frustrating.

Gaining Your Insurance Company's Approval

Gaining Your Insurance Company's Approval

Before we can commence repairs on your car, they need to be inspected and approved by your insurer. All insurance companies have their own proceedures and gaining approval can take time. We will do everything in our power to get this authority as soon as possible. Our customer service staff will call you after the insurance inspection and explain how the assessment went and exactly what the assessor has approved. If there are delays in the authorisation of your claim we will notify you immediately.

Dismantling & Quotation

Dismantling & Quotation

At this stage each vehicle is disassembled to expose all hidden damage. A quotation is prepared and all parts are pre ordered. An expected repair time is then established.

Parts Ordering

Parts Ordering

Once your car has been authorised for repair we will confirm the parts order. Sometimes parts come from interstate and sometimes from overseas (for example, Japan or Germany). We will notify you immediately of any part delays.

Customer Updates

We will phone or email you upon car authorisation. Our customer service staff will ring you with further updates as required, especially with more complex jobs. If at any time you have a query do not hesitate to call customer service on 02 9476 2558

Panel & Structural Repairs

Panel & Structural Repairs

At this stage each vehicle is measured and reset using manufacture approved aligning equipment, to ensure the settings match factory specifications. All repair work is conducted in strict compliance with the manufacturer's specifications. Each vehicle is subject to quality assurance check list by production manager before progressing to the paint shop.

Prepare and Paint

Prepare and Paint

Each vehicle's paint thickness is measured and checked against manufacturers specifications. Vehicle's are then prepped and masked ready for painting. This includes sanding, hi-fill and curing, and dust extraction. The surface condition of each vehicle and its panels are inspected prior to painting. Paint is applied in a dust free, climate controlled spray booth. The vehicle is then baked at a set temperature and time to allow for paint curing. This will ensure paint durabillity and a factory quality finish.

Buff & Denib

Buff & Denib

Once the fresh paintwork has dried, the vehicle is unmasked and de-nibbed to remove any minor imperfections in the paintwork. The vehicle and panels are then machine buffed and polished.

Reassembly

Reassembly

At this stage each vehicle is reassembled and a fitment quality check ensures that all parts and panels are fitted in accordance with manufacturers specifications. Each vehicle is then road tested and mechanical checks are performed where necessary, to ensure the vehicle functions as it did prior to repairs.

Wash, Vacuum & Inspection

Wash, Vacuum & Inspection

Finally, each vehicle is washed and vacuumed to a high standard and a complete quality inspection is conducted.

Quality Workmanship

When it comes to repairs, you cannot compromise on quality. Our rigorous quality assurance systems ensure that each vehicle is thoroughly checked at the end of each repair stage prior to proceeding. This results in a finished product of the highest possible standard.

Warranty on All Repairs

Warranty on All Repairs

Our repairs are carried out to factory standard and covers. Quality of workmanship and repairs made to your vehicle. Repairs and replacements that have been carried on your vehicle are in accordance with manufacturer specifications.